LITERATURE REVIEW: PENGARUH SUHU AIR ECONOMIZER DAN FLOW STEAM TERHADAP EFISIENSI BOILER CFB

DOI:

https://doi.org/10.31949/j-ensitec.v11i02.13607Abstract

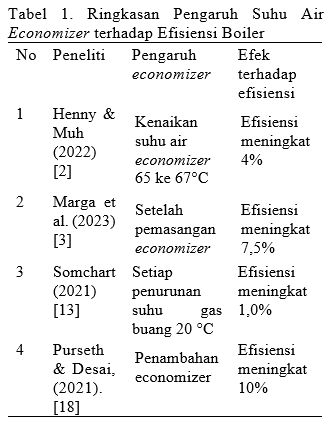

This study aims to analyze the effect of economizer water temperature and steam flow on boiler operational efficiency in Circulating Fluidized Bed (CFB) type Steam Power Plant (PLTU). The study was conducted through a literature review of a number of recent studies that examined the relationship between these two parameters and the thermal efficiency of the boiler system. The analysis shows that increasing the economizer water temperature from 65°C to 67°C can increase the efficiency up to 4%, while installing economizer in general can increase the efficiency up to 10%. On the other hand, excessive steam flow variation can cause temperature fluctuations and decrease efficiency, while optimal steam flow regulation is proven to increase heat recovery from flue gas and decrease operating costs. The optimal interaction between economizer water temperature and steam flow is proven to save fuel, reduce greenhouse gas emissions, and extend the service life of boiler components. This study concludes that the implementation of automatic control and real-time monitoring of both parameters is essential to improve energy efficiency, reduce maintenance costs, and support the sustainability of power generation systems.

Keywords:

PLTU, Boiler, Economizer, Efficiency, PLTU, boiler, economizer, flow steam, efficiencyDownloads

References

[1] Alyah, S., dan A. Sulton. 2023. Efficiency analysis of fire tube boiler type at refinery utility unit center for oil and gas human resources development (PPSDM MIGAS) Cepu. Jurnal Cakrawala Ilmiah, 2(7): 3109-3118.

[2] Henny, N. P., dan R. S. Muh. 2022. Analisis pengaruh temperatur air economizer terhadap efisiensi ketel di KM Meratus Kupang. Venus, 10(1): 13-25.

[3] Marga, M., A. Nurul, dan Soeprijanto. 2023. Efisiensi boiler dengan penambahan alat economizer sebagai pre-heater steam. Jurnal Teknik ITS, 12(3): 155-160.

[4] Zhongyuan Liu, S. M., dan J. C. Xiongfeng Pan. 2019. Experimental study on the load response rate under the dynamic combined combustion of PC coal and CFB coal in a CFB boiler. Fuel, 236: 225-251.

[5] Nuraini, A. A., S. Salmi, dan A. H. A. 2018. Efficiency and boiler parameters effects in sub-critical boiler with different types of sub-bituminous coal. Iran J Sci Technol Trans Mech Eng: 1-11.

[6] Nabila, S. T., S. M. Jayusandi, dan A. Lisa. 2022. Analisis efisiensi boiler menggunakan metode langsung di Pembangkit Listrik Tenaga Sampah (PLTSa) Bantargebang. Journal of Engineering Environmental Energy and Science, 1(1): 39-48.

[7] Sulton, A., W. Anggi, dan P. Apriliansyah. 2023. Analisis efisiensi boiler tipe circulating fluidized bed (CFB) dengan metode langsung di PT XY. Jurnal Teknik Patra Akademika, 14(2): 101-108.

[8] Yuge Yao, R. C., Z. Y. Liu, dan H. Y. J. L. Man Zhang. 2019. A method to measure the tube-wall temperature in CFB boilers. Applied Thermal Engineering, 153: 493-500.

[9] Bima, P. R., M. K. Lukas, dan G. Yuspian. 2021. Analisis pengaruh nilai kalor batubara dan excess air terhadap efisiensi boiler di pembangkit listrik PLTU Moramo. Jurnal Ilmiah Mahasiswa Teknik Mesin, 6(1): 12-17.

[10] Sirait, F. Aneka, dan Erwin. 2015. Analisa pengaruh variasi kapasitas uap terhadap efisiensi ketel uap di PT. Sinar Sosro Banyuasin-Sumatera Selatan. Jurnal Energi dan Manufaktur, 8(2): 133-140.

[11] Rif’ah, A., Fahmi, dan Joke. 2021. Pengaruh serrated finned tube terhadap perpindahan panas economizer menggunakan ANSYS CFD. Series: Engineering and Science, 7(1): 512-519.

[12] Moh, M., dan E. Dino. 2023. Analisa efisiensi menggunakan energi alternatif economizer pada boiler. Formosa Journal of Science and Technology (FJST), 2(8): 2225-2238.

[13] Somchart, C. 2021. Optimum installation of economizer, air heater, and flue gas dryer in biomass boiler. Computers and Chemical Engineering, 150(107328): 1-10.

[14] Chaerul, A. Q., dan A. Joon. 2023. Designing a turning guide vane using CFD for an economizer of a non-furnace boiler. Processes, 11(1617): 1-13.

[15] Doddi, Y., dan R. Puspita. 2023. Meningkatkan efisiensi pengendalian suhu boiler pada PLTSa Burangkeng melalui analisis komprehensif berbasis machine learning. Jurnal Teknik dan Science, 2(3): 17-28.

[16] Siti Rofifa Salim & Herlina. 2024. Analisis Manajemen Risiko Operasional Bongkar Muat Menggunakan Metode Hor. J-ENSISTEC (Journal of Engineering and Sustainable Technology).vol 10. No.2. 1070-1076

[17] Wahyu, A. D., Rivandi, H., Fawwaz, G. Y., & Nawang, K. (2024). DAMPAK EMISI KARBON PESAWAT UDARA: TANTANGAN DAN SOLUSI UNTUK PENERBANGAN BERKELANJUTAN. Jurnal Review Pendidikan dan Pengajaran, 7(2), 3493–3502.

[18] Purseth, J. D. S., & Desai, M. S. (2021). PERFORMANCE ANALYSIS AND EFFICIENCY IMPROVEMENT OF BOILER: A REVIEW. International Journal of Engineering Applied Sciences and Technology, 5(12), 326–331.

[19] Suryaman & Noordianto. 2023. Analisa Hasil Uji Kompresor Sistem Refrigerasi Menggunakan Inverter. J-ENSISTEC (Journal of Engineering and Sustainable Technology).vol 10 No.1. 966-971

[20] Ravinder, K., Ravindra, J., Mohammad, A. H., & Rajneesh, K. (2019). A simulation model for thermal performance prediction of a coal-fired power plant. International Journal of Low-Carbon Technologies, 14, 122–134.

[21] Nurhasanah & Roswati. (2015). Perbandingan Efisiensi Boiler Awal Operasi dan Setelah Overhaul Terakhir di Unit 5 PLTU Suralaya. Jurusan Teknik Mesin, Sekolah Tinggi Teknik – PLN, 2356(1513), 44–48.

[22] Hendra, S. M. O., Ir, M. F. R., Jamal, G. S. M. D., & Bahrun. (2019). ANALISIS PENGARUH KERAK DARI HASIL PEMBAKARAN BAHAN BAKAR MINYAK RESIDU TERHADAP PRODUKSI UAP PADA BOILER TIPE EMO KAPASITAS 5 TON. Seminar Nasional Teknologi, Sains dan Humaniora, 187–193.

[23] Sidiq & Noor, A. (2022). Pengaruh Co-Firing Biomassa terhadap Efisiensi Boiler PLTU Batubara. KILAT, 11(1), 21–31.

[24] Pengcheng, X., Yanping, Z., Yuanjing, W., & Jizhou, W. (2019). Analysis of an improved economizer system for active control of the coal-fired boiler flue gas temperature. Energy, 170, 185–198.

[25] Russul, H. M., H. A. H., & Ali, H. N. (2021). An Experimental Investigation of The Dynamic Effects in Upper Drum Boiler Under Steam Mass Flow Rate Variation. Engineering and Technology Journal, 39(9), 1376–1383.

[26] Xiaozhou, L., Guangyu, Z., Yu, Z., Taimoor, A., & Mishra, R. (2019). Performance improvement of a Circulating Fluidized Bed Boiler through flow modifications in Primary Air Supply System. International Journal of COMADEM, 29–43.

[27] Imam, U. S., & Djatmiko, I. (2019). Experimental Study: The Effect of Excess Air to Unburn Carbon and Boiler Efficiency Using Coal with Heating Value 4200 kcal/kg at a 500 MW Steam Power Plant. AIP Conference Proceedings, 2187(020030), 1–6.

[28] Uzair, I., & Sarah, F. (2019). Optimization of Fuel in Saturated Steam Boiler through Preheating of Controlled Air-Fuel Mixture. Mathematics and Engineering Technologies–iCoMET, 978, 1–6.

[29] Somchart, C. (2022). Investigation of the use of steam coil preheater to increase the net efficiency of thermal power plant. Case Studies in Thermal Engineering, 38(102344), 1–9.

[30] F. S. D. A. & Purwanto, M. R. (2020). Analysis of Boiler Engine Efficiency Unit 2 PT. PJB UP Paiton. Journal of Physics: Conference Series, 1805, 1–11.

[31] Marcell, B. H., & Nazaruddin, S. Dr. Ir. (2023). ANALISIS EFISIENSI WATER TUBE BOILER MENGGUNAKAN METODE LANGSUNG DI PT. TOBA PULP LESTARI, Tbk PORSEA-SUMATERA UTARA. Jurnal Teknik Mesin S-1, 11(2), 49–68.

[32] Dadang, M., Dani, R., & I., N. (2023). Desain Pembangkit Listrik Turbin Uap Berbahan Bakar Batu Bara yang Efektif dan Ramah Lingkungan. Jurnal Tekno Insentif, 17(1), 58–68.

[33] Arthur, D., Lucas, C., Nayana, A., Suenia, V., Romildo, B., & Karoline, B. (2020). Simultaneous prediction of steam production and reduction efficiency in recovery boilers of pulping process. Journal of Cleaner Production, 275(124103), 1–14.

[34] Carrie, S., Colin, J. Z. M., Jennifer, D., & Masanet, E. (2022). Electrification potential of U.S. industrial boilers and assessment of the GHG emissions impact. Advances in Applied Energy, 5(100089), 1–13.

[35] Wei, T., Huijun, F., Lingen, C., Zhuojun, X., & Junchao, S. (2021). Constructal design for a boiler economizer. Energy, 223(120013), 1–10.

[36] Xiaoqu, H., Tianrun, Y., Dan, Z., Yanbing, D., Jinping, L., & Junjie, Y. (2021). Waste heat utilization from boiler exhaust gases for zero liquid discharge of desulphurization wastewater in coal-fired power plants: Thermodynamic and economic analysis. Journal of Cleaner Production, 308(127328), 1–15.

[37] Saravanan, G. K., Sivapragasam, A., Padmavathy, S., Sivaraj, M., Mebratu, T., & Godwin, A. A. (2022). Analysis of fin characteristics for overall heat transfer in boiler economizer. Thermal Science, 26(2), 849–855.

[38] B. R., Ganapathyraman, G., P., M., Prabakaran, A., & S., P. (2016). Performance Analysis of Economiser, Air Pre-Heater and Electrostatic Precipitator of 210MW Power Plant Boiler. International Journal of Engineering Research And Advanced Technology (IJERAT), 2(4), 7–13.

[39] Chantasiriwan, & Somchart. (2021). Optimum installation of economizer, air heater, and flue gas dryer in biomass boiler. Computers and Chemical Engineering, 150(107328), 1–10.

[40] Peng, D., Ben, W., Cai, X., & Lei, B. (2022). Research on the Modification of Coal Adaptability and Carbon Emissions Reduction Technology for Coal-Fired Boilers. Energies, 15(9533), 1–12.

[42] Paweł, Z., Natalia, S.-K., Butterweck, A., Michał, S., Stanisław, G., Marta, D.-K., Anna, M., & Jerzy, G. (2021). Comprehensive thermodynamic analysis of steam storage in a steam cycle in a different regime of work: A zero-dimensional and three-dimensional approach. Journal of Energy Resources Technology, 143(10), 1–29.

[43] Ducardo, L., Juan Ricardo, M. V., Alexis, G. S., Juan, E. J. C., Jesús, A. L., Simón, H., & Enrique, C. Q. (2023). Multiobjective Optimizatin of the Energy Efficiency and the Steam Flow in a Bagasse Boiler. Sustainability, 15(11290), 1–17.

[44] Putri, N. A. Z., Yuliani, I., & Widarti, S. (2024). Pengaruh Pemakaian Jenis Bahan Bakar Terhadap Kinerja Boiler dengan Metode Langsung dan Tidak Langsung. Jurnal Surya Teknika, 349–356. https://doi.org/10.37859/jst.v11i1.7324

[45] Hao, Z., Yong, D., Yanhua, L., Hao, Z., & Xinbo, Z. (2020). Waste heat recovery from coal-fired boiler flue gas: Performance optimization of a new open absorption heat pump. Journal Pre-proofs, 1–32.

[46] Mahmmod, A.-S., Ali, A., & W. A. (2021). A Series Arrangement of Economizer – Evaporator Flat Solar Collectors as an Enhancement for Solar Steam Generator. Journal of Ecological Engineering, 22(5), 121–128.

[47] Chamorro, M. V. (2024). Operational Control of the Energy Performance of a Water-Tube Boiler Using Intelligent Monitoring of Operating Variables and Parameters. EUREKA: Physics and Engineering, (3), 45–60.

[48] Paweł, M., & P. (2020). Calculation methods of steam boiler operation factors under varying operating conditions with the use of computational thermodynamic modeling. Energy, 197(117221), 1–12.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 faizal, Nanang Ruhyat

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

An author who publishes in the J-ENSITEC (Journal of Engineering and Sustainable Technology) agrees to the following terms:

- Author retains the copyright and grants the journal the right of first publication of the work simultaneously licensed under the Creative Commons Attribution-ShareAlike 4.0 License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal

- The author is able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book) with the acknowledgment of its initial publication in this journal.

- The author is permitted and encouraged to post his/her work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of the published work